This evaluation helps prioritize cleaning endeavours and give attention to crucial regions that pose the highest threat to solution high-quality and individual safety.

The product picked from a gaggle of products which signifies the best risk of carry-above contamination to other products and solutions manufactured in the same gear by advantage of its lousy solubility, potency, and toxicity, or a combination of these elements.

These kinds of an excellent critique about your pointed out write-up. You Internet site is great searching. Our company is modular kitchen chennai price listing area. How you are feeling about soon after gst for kind of organization in india.

This possibility evaluation — knowledgeable by our proprietary Extractables Simulator (ExSim) platform, which predicts the concentration of extractables for one-use devices and assemblies and scales facts appropriately determined by system requires — is the complete first step of one's validation

Reporting & documentation: At this time, companies document the final results of their cleaning validation approach in an extensive report.

The importance of extractables & leachables screening has developed with greater utilization of one-use programs. Hence, E&L tests is actually a regulatory requirement to demonstrate that leachable impurities from plastic resources Employed in the processing of the health care product or service don’t interfere Along with the Energetic pharmaceutical ingredient, guaranteeing patient protection.

Restrict of detection and limit of quantification shall be reported by QC once the establishment with the analytical method in

Moreover, the term “cleaning” also features the whole removal of cleaning brokers that were utilized in the course of the cleaning approach.

You’ll continue to should validate your cleaning methods when applying committed tools for certain processes.

A cleaning validation for your household of compounds utilizing swab sampling and rinse Remedy processes, and high effectiveness liquid chromatography for separation and detection with the analytes was carried out.Powerful parameters on recovery which include sampling method, swab properties, solvent, swabbing strategy, and materials compound of products contact surfaces throughout the production machines for swab and rinse sampling method, quantitative cleaning verification method, and active pharmaceutical component (API) level and character have been analyzed.The Restrict of detection along with the Restrict of quantitation for your HPLC check here method ended up determined to be 0.0198 µg/mL, and 0.0495 µg/mL on the analyte, respectively.

By using NOEL and MACO, we can discover out the amount of the drug that could not be carried out above to the following batch. As scientific studies previously mentioned 250mg /kg LD50 shouldn't be in excess of 0.25gm in the next batch as per earlier mentioned the batch has 350mg every day dose and one hundred kg batch dimensions.

Cleaning validation protocols sort an integral Section of the process used to take care of merchandise high-quality & security throughout numerous more info industries. Below are a few situations any time a cleaning validation process will be practical:

• use distinct protection aspects for various dosage types dependant on physiological reaction (this method is important for potent resources).

The statement could be justified as though worst-situation products in the worst products chain (owning greatest area location) are validated correctly,

Emilio Estevez Then & Now!

Emilio Estevez Then & Now! Sam Woods Then & Now!

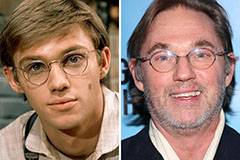

Sam Woods Then & Now! Richard Thomas Then & Now!

Richard Thomas Then & Now! Lisa Whelchel Then & Now!

Lisa Whelchel Then & Now! Dawn Wells Then & Now!

Dawn Wells Then & Now!